ECT 263 Week 5 Lab Assignment Help | Devry University

- Devry University / ECT 263

- 26 Jun 2019

- Price: $25

- Other / Other

ECT 263 Week 5 Lab Assignment Help | Devry University

iLab5—Phase Locked Loop S-curve Using

Tutor*Tims

(Filename convention:

first initial last name PLLTT1 .doc)

Part A—Experiment Setup

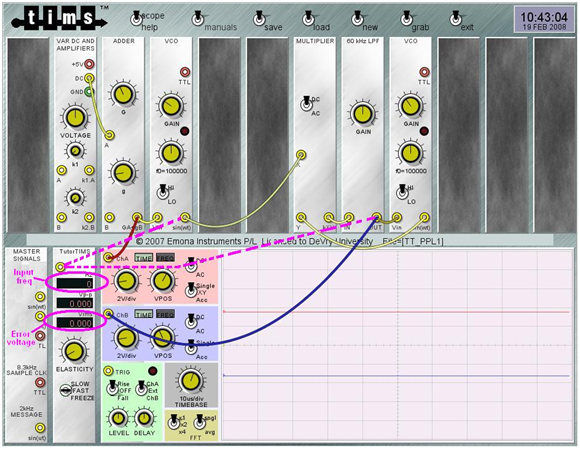

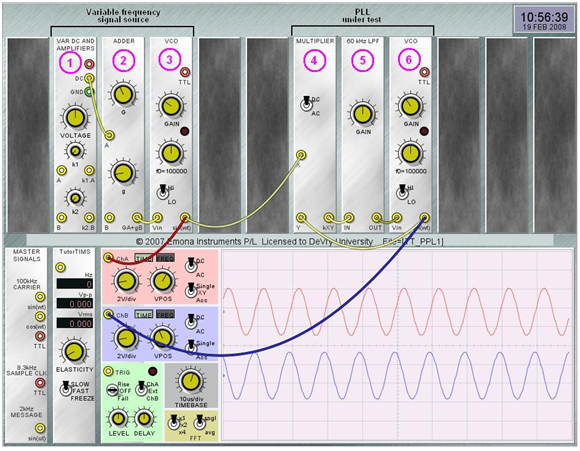

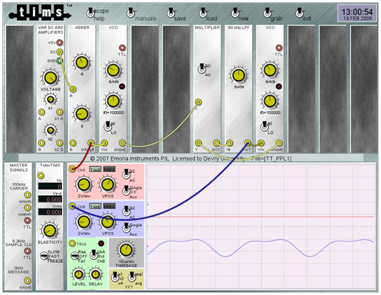

Figure 1

This circuit consists of two sections; the variable

frequency signal source (modules 1–3) and the phase locked loop itself (modules

4–6).

You can use the positions of the knobs shown as a

starting point. One setting that is particularly important is that the idle

frequency of the signal source VCO and the PLL VCO must be the same. In this

case, note that both are set for f0 = 100000. Both of the VCO’s idle

frequencies are set to 100KHz.

The Voltage control on the Variable DC and Amplifiers

module (module 1) controls the voltage to the signal source VCO and hence its

frequency.

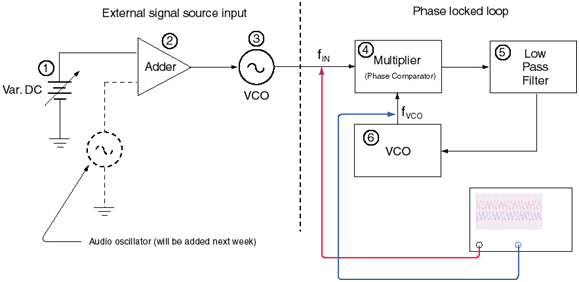

The figure below shows a block diagram of what we have created thus far.

The oscilloscope traces show that the PLL’s VCO is

synchronized with the incoming signal source’s VCO.

What you need to do is to vary the input frequency (by

varying the voltage produced by the Variable DC [module 1]) and seeing what

effect that has on the PLL.

We want to create an S-curve characteristic of the PLL

that shows the tracking range where the PLL’s VCO is locked onto the incoming

signal. To do this, we will need to vary the input frequency and measure the

error voltage as the PLL’s VCO adjusts to stay in sync with the incoming signal.

We will need to use Tutor*Tims’ built-in metering to do this.

On the bottom half of Tutor*TIMS you will see a module

just to the left of the scope titled simply Tutor TIMS. This module has an

input that can be used to measure frequency and voltage. The module also has a

control labeled Elasticity, which controls the droopiness of the wires and a

switch that controls the speed of the signal processing. Set the speed switch

to Fast.

In the process of taking our measurements, we will

need to switch between the voltmeter function and the frequency counter

function. Figure 3 below shows the alternating connections to take these

measurements.

Figure 3

The dashed purple lines show the two alternate

connections that we will be using to take our measurements. When you connect

the metering unit to the VCO output (module 3), you will be measuring the input

frequency applied to the PLL from the variable signal source. When you connect

the metering unit to the 60KHz LPF (module 5) you will be measuring the

resulting error voltage needed to keep the PLL’s VCO in sync with the incoming

signal.

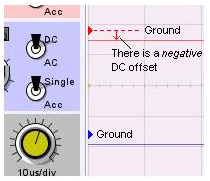

Initially in Figure 1 above, the scope was displaying the outputs of the two VCOs. Now, in Figure 3, it’s displaying the DC voltages applied to the VCOs. Figure 1 shows a more traditional view of a PLL where one can see whether the two signals are in phase or not. In this experiment, we need to measure the RMS value of the DC error voltage. If you’ll recall from your basic electronics, RMS is the DC equivalent of an AC signal. There is no such thing as a negative RMS voltage. So, to help us out we will use the scope, which can show a DC offset just fine, to tell us whether the number that we read on the RMS voltmeter is positive or negative. Look for two small triangles on the scope display (Figure 4).

Part B—Recording Your Data

Now you are ready to record your data. Open an Excel spreadsheet. Label the left-hand column fIN. Label the right-hand column Error voltage. Start by connecting the metering input to the error voltage output of the low-pass filter (module 5). Wait for the voltage to stabilize. Record the voltage (paying attention to whether it’s above or below the ground reference on the scope. Move the metering input lead to the output of the PLL VCO (module 6) and record the frequency. (The graphic above the display may say Hz but in this case it is actually KHz.)

Move the metering input back to the error voltage. Gradually change the input frequency by adjusting the DC voltage produced by the variable DC source (module1). Again, wait for the reading to stabilize and record it. Move the lead back to the input frequency (output of the first VCO [module 3]) and again record the frequency.

Construct a table of data in Excel. In all, you should have 5–10 data points within the tracking range and two to three above and two to three below the tracking range. fIN is your independent variable that you record in the left-hand column in Excel. Keep your data points in order. That is, make sure that your data goes from the lowest frequency to the highest frequency like what was done in the lecture section in eCollege. We want to see what happens to the error voltage as we vary the input frequency.

Figure 5 below shows what the error voltage will look like when you exceed the tracking range in either direction.

The blue trace is the error voltage output of the

low-pass filter. You can see that it jumps around wildly as the PLL tries—unsuccessfully—to

stay synchronized with the input signal.

Part C—Plotting Your Data

Once you’ve recorded enough data points in your

Excel table, highlight the entire table (including the headings) and select the

Chart Wizard. Then select x-y scatter plot and format the graph as you see fit.

(Titles, background, etc., is your choice.) Make sure that all of your data is

clearly understandable to the reader

Use the Grab button to capture a sample of your

circuit and paste it into the PLLTT1 answer sheet. It doesn’t matter which data

point you grab—just a typical representative screen shot of your experiment in

progress.

Copy your data table from Excel and paste it into the

answer sheet.

Copy your completed graph from Excel and paste that

into the answer sheet.

Submit your answer sheet document to the eCollege

Dropbox.

USA

USA  India

India

Question Attachments

1 attachments —